Our dimensional measurement laboratory, which is a calibration laboratory accredited by the National Accreditation Authority under identification number NAH-2-0334/2022, offers the following services:

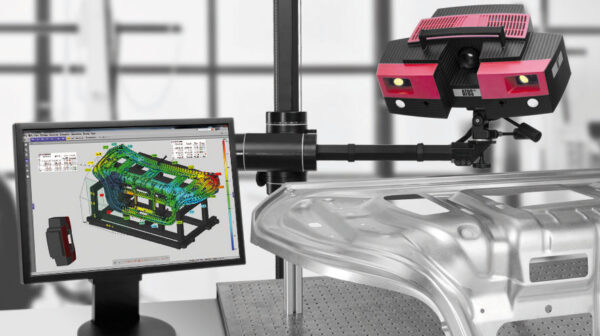

With our manually operated Triple Scan surface scanner, we are able to digitalize tools at the customer’s premises or items with a size ranging from the tip of a needle to a car in a laboratory environment. Our engineers then analyze the results and write a report about them.

A non-accredited service of ours built on the activities above is reverse engineering which enables us to manufacture work pieces without proper documentation (CAD model) and, upon request, prepare product drawings.

ScanBOX, i.e. our robot-assisted surfaces scanner, is perfectly suitable for performing repeated measurements as well as machine and process capability tests.

Our ZEISS Contura coordinate-measuring machine is used together with optical scanners mainly for work pieces which do not need ‘blowing down’ before measurement.

It is suitable for the digitalization of items with a size ranging from the tip of a needle to a car. Its main advantage is the high density of captured points, which enables us to carry out measurements anywhere on the surface. It is portable, which means that scanning can be performed at any place. Eternal data storage in STL format – point clouds scanned in the past are also available.

It is perfectly suitable for repeated measurements where up to 30-40 parts must be scanned per cavity in the case of multi-cavity production settings. It is mainly used for machine capability and process capability tests.

It is able to capture a grid of points with a size of up to 15 meters in length when photogrammetry measurements are carried out. It accurately defines the coordinates of measurement points on the object to be measured. With the help of this system, the measuring range of optical scanners can be extended. It is our most compact optical measurement tool; as a result, it can be easily used for on-site measurements.

With the help of our Zeiss CMM, we are able to offer the highest possible precision to our customers, coupled with exceptional reliability. It ensures high precision point-to-point measurement without the need for any surface preparation (non-destructive). The measured features can be displayed graphically, resulting in project reports including all the necessary information. It is a measuring device that is suitable for a large number of repeated measurements.

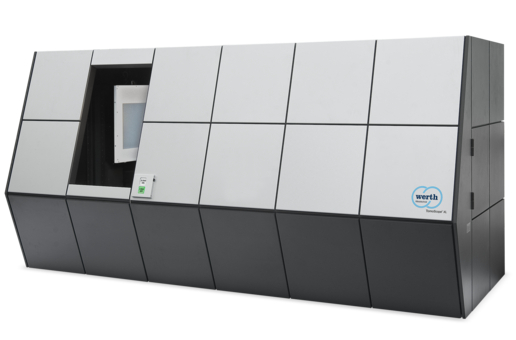

It provides a 3 dimensional image (STL) of non-conspicuous, hidden or narrow internal surfaces. The image then becomes measurable after it has been imported into CAD systems. It is perfectly suitable for carrying out failure analyses, identifying shrinkage cavities and performing leakage tests.

Its main advantage over 3D optical scanners is that it can also be used for the digitalization of non-conspicuous surfaces. It is able to create a point cloud (STL file) that optical scanners and thus CAD system can read; as a result, any measurement can be carried out on the 3 dimensional cloud captured from the inner geometry of the work piece. For failure analysis, functional tests can be performed and analyzed. The identification of shrinkage cavities is another useful feature: the program is able to tell where, in what amount, what volume and what diameter air bubbles can be found in the material of the workpiece – this can be important in the case of cracks and fractures.

Industrial CT machines work exactly the opposite way than human CT devices do: here, the workpiece is revolving on a rotary plate, slowly but continuously, while a large number of images are taken of it. The images are linked in 3D by the program, resulting in an enormous amount of data.

For the identification of inner defects, videos and images can be taken through the product being scanned, in the planes specified by the customer. Regarding prices, it is important to know that the smaller the workpiece, the lower the ‘per piece’ price is, which means that with certain products, this may be the cheapest measurement method – please note that the size of the workpiece is just one aspect; it is equally important that it must have the specified tolerance limits and it must be mono-material (i.e. composed of a single type of material).

Request an offer in 2 minutes!