Creating 3D CAD/CAM models of products in all the well-known file formats and, upon request, dimensioned 2D drawings, views and cross-sections

With our top class industrial GOM full-surface optical measurement equipment (3D scanner) or our Werth CT (Computed Tomography) device and the related optical image processing system, we offer our services for the high resolution and precision digitalization of a range of products, from really small (precision mechanical) parts to articles, products, pieces or tools of any material or color and of a size of up to several meters. Using the point cloud captured during the full-surface 3D scanning of the product, we are able to reconstruct 3D CAD models, organizing the data into a coordinate system. The model can be reconstructed with a surface-fitting or a reverse engineering method, depending on quantity and the customer’s needs. In both cases, the precisely measured data are idealized, which means that CAD geometric components which most closely resemble the geometric components of the scanned product will be fitted.

The output is basically a STP/STEP format (body) model, however, upon request, any format is possible.

Typical areas of use: reconstruction of damaged, broken or unavailable parts or electrodes; if no identical parts or 2D/3D drawings of a tool are available; or the duplication of a model, typically an old tool.

Naturally, reverse engineering is also possible using the point cloud provided by the customer.

Explaining the process through an example:

Original piece:

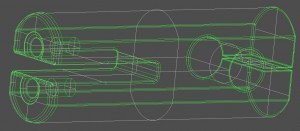

3D grid:

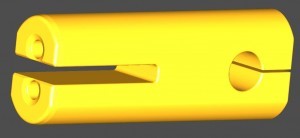

3D body model:

Request an offer in 2 minutes!